Stevens Pottery

1882

April 14, 1882

The Atlanta Constitution

Stevens Pottery Ga, April 7, 1882

Last Tuesday morning your correspondent took the Macon and Eatonton trail for

this little village. At nine o'clock he landed in the place and proceeded to

take notes of the surroundings. "The Pottery," as it is called, was settled long

years ago by Mr. Henry Stevens, and here he made money at the business, which

has since engaged his sons-Crawford, John Henry and William Park. The increasing

trade, and his declining health, made it necessary for the old man to give up

most of his business to his boys. He brought them up to work, and they were

fully competent to take charge of it. Really, the business has all passed into

their hands, and the father employs his time in traveling for the firm.

The first thing which attracts the attention of the stranger is an ungainly

looking building, on the southeast of the railroad. At the entrance one is

saluted by "mud" -right and left. This mud is dug up one mile from the building,

and brought by the railroad to this point. It is thrown in a pit to soak for

several hours, and then fed into the mud mill. This mill is run by a twenty-five

horse power engine in the west side of the mud-room. After passing though the

mud mill the clay is ready for the potter's use. If for drain pipe, of which

large numbers are made, it is thrown, in a large lump into a press run by the

same engine as the mud mill, and forced through a die-which may be taken off or

put on at pleasure-the size of which determines the size of the pipe. Two bands

hold the receptacle - a wooden piece curved to fit the pipe. When the proper

length has been reached the pressure is stopped, and a wire is needed to cut off

the dirt tube. To follow this particular branch further; the pipe is taken to

another room where any roughness may be smoothed off, and a "collar" put on.

This is done by standing it upon a table placing a roll of mud around the top or

collar and pressing the mud with the hand to the size necessary to receive a

pipe of the same size as the one "collared."

The pipe is taken to the "dry-pan" a room some

thirty by ninety feet square. Large flues pass through the dirt floor, which

conduct the heat to all parts of the room. This drying prepares the pipe for the

glaze vat. Here it is swung into a solution of "blue mud." This is not ordinary

mud, but is of a peculiar character, and cost several dollars per barrel. It is

shipped from Albany, New York. After a few hours drying, it is placed in the

large kiln, and burned until it comes to a white heat. This melts the blue mud

and causes it to form a beautiful glaze. The kiln is then opened and left to

cool, when the pipe is removed to the pipe yard, where such large numbers are

seen, there to await orders. It is manufactured from two inches to two feet in

diameter.

1893

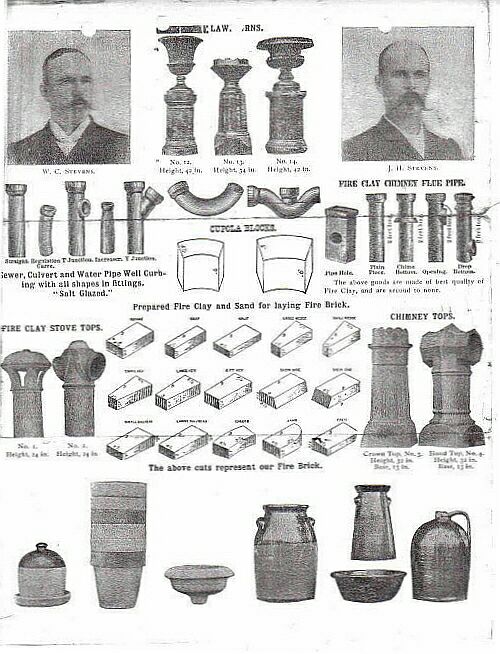

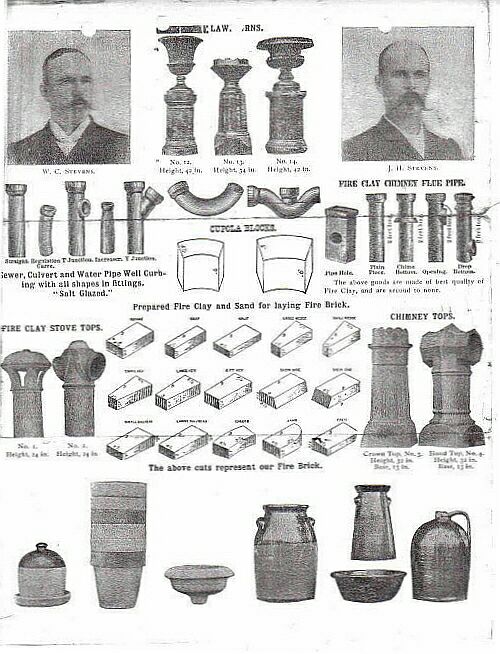

Copy of a letter that was received at the War Department from Stephens Pottery

regarding my great-grandfather, George F. Swan who worked at the Pottery for

about 8 years. They apparently enclosed the second paper with pics of W. C.

Stevens and J. H. Stevens shown with different types of pottery made at Stephens

Pottery, just because....... They were two separate papers received by me from

the War Department in my great-grandfather's pension file. They were dated

1893. My great-grandfather apparently moved around alot and after leaving

Stevens Pottery could not be found for a couple of years. His pension file was

over 400 pages. Tonya Crosby

Copy of a letter that was received at the War Department from Stephens Pottery

regarding my great-grandfather, George F. Swan who worked at the Pottery for

about 8 years. They apparently enclosed the second paper with pics of W. C.

Stevens and J. H. Stevens shown with different types of pottery made at Stephens

Pottery, just because....... They were two separate papers received by me from

the War Department in my great-grandfather's pension file. They were dated

1893. My great-grandfather apparently moved around alot and after leaving

Stevens Pottery could not be found for a couple of years. His pension file was

over 400 pages. Tonya Crosby

Submitted by Tonya Crosby